Upgrades

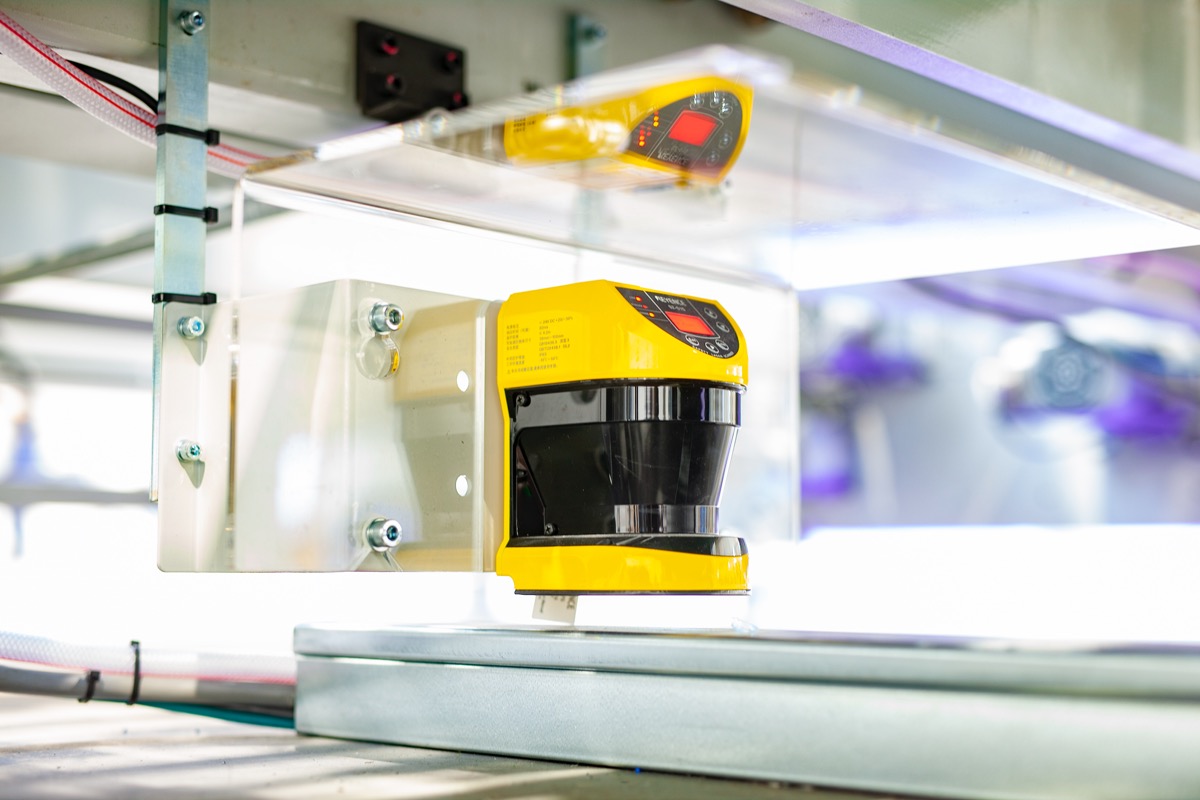

As soon as the JD Machine control is equipped with one or more servos or frequency drives, a safety CPU with safety I/O will be added to the system. This safety CPU controls all motion parts and will switch off the drives in to a safe mode. Stop and emergency stop buttons as well as light curtains, area scanners, sensors and safety mats can be connected to the special inputs of the JD Machine safety I/O to create a safe environment for the operators.

The main computer has two versions:

JD Main computer FD is equipped with frequency inverters. These control the speed of the machine. The drives have built-in security and are connected to the security CPU of the JD operating system.JD Main-Drive SD is equipped with servo drives. Each section will be equipped with one or more servo drives. These drives control the speed of the machine and the position of the boxes in all sections. When an error is detected (see also JD Jam detection and JD Glue detection), the machine is switched off section by section. This results in less waste. Especially when hot-melt glue is used.

JDIS is the JD online support system.

With this system we can:

– Check the drive’s condition.

– Check the settings and change / adjust if necessary.

– Read out the log files to analyse faults more easily.

– Perform software updates

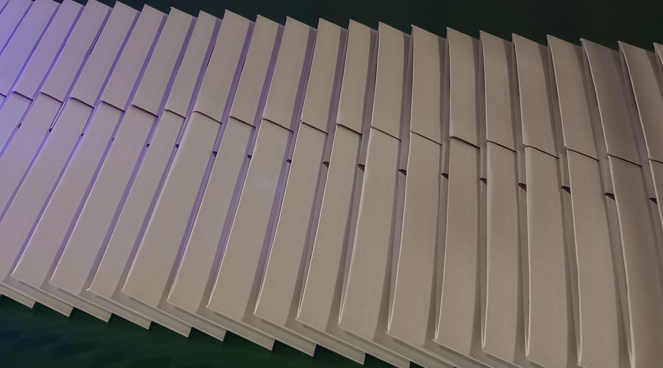

– Take control for e.g. training purposes or in case of problems.The device is specially designed for shorter boxes that are difficult to stack for the conveyor. It can do straight line, crashlock and RSC boxes up to about 20,000 pcs/h. processing (Depending on format and type).

Type A is usually mounted on Press Conveyors with a maximum width of 1200 mm.

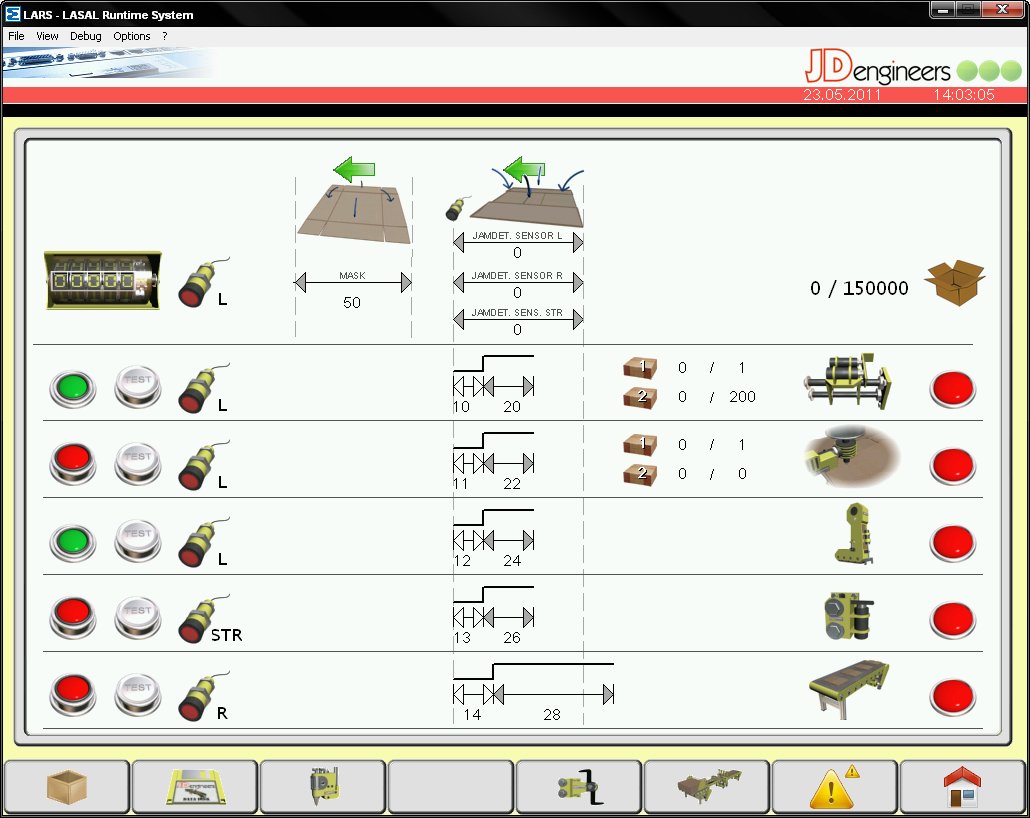

Type B is usually mounted on Press Conveyors from 1200 mm.The JD conveyor control detects the flow of boxes in the folder gluer. Based on the number of boxes per hour, the conveyor belt speed will increase or decrease to ensure a constant flow through the conveyor. The desired overlap can simply be entered and the machine does the rest. Deviating distances between the boxes hardly affect the conveyor.

The counter can be connected to the JD main computer. All set values are then saved for a repeat order The counter has a “dual” function, so that even odd quantities can be counted (like 12/13). The conveyor, the LSU aligner, the counter kicker and the “jam” detection are all controlled by the JD counter.

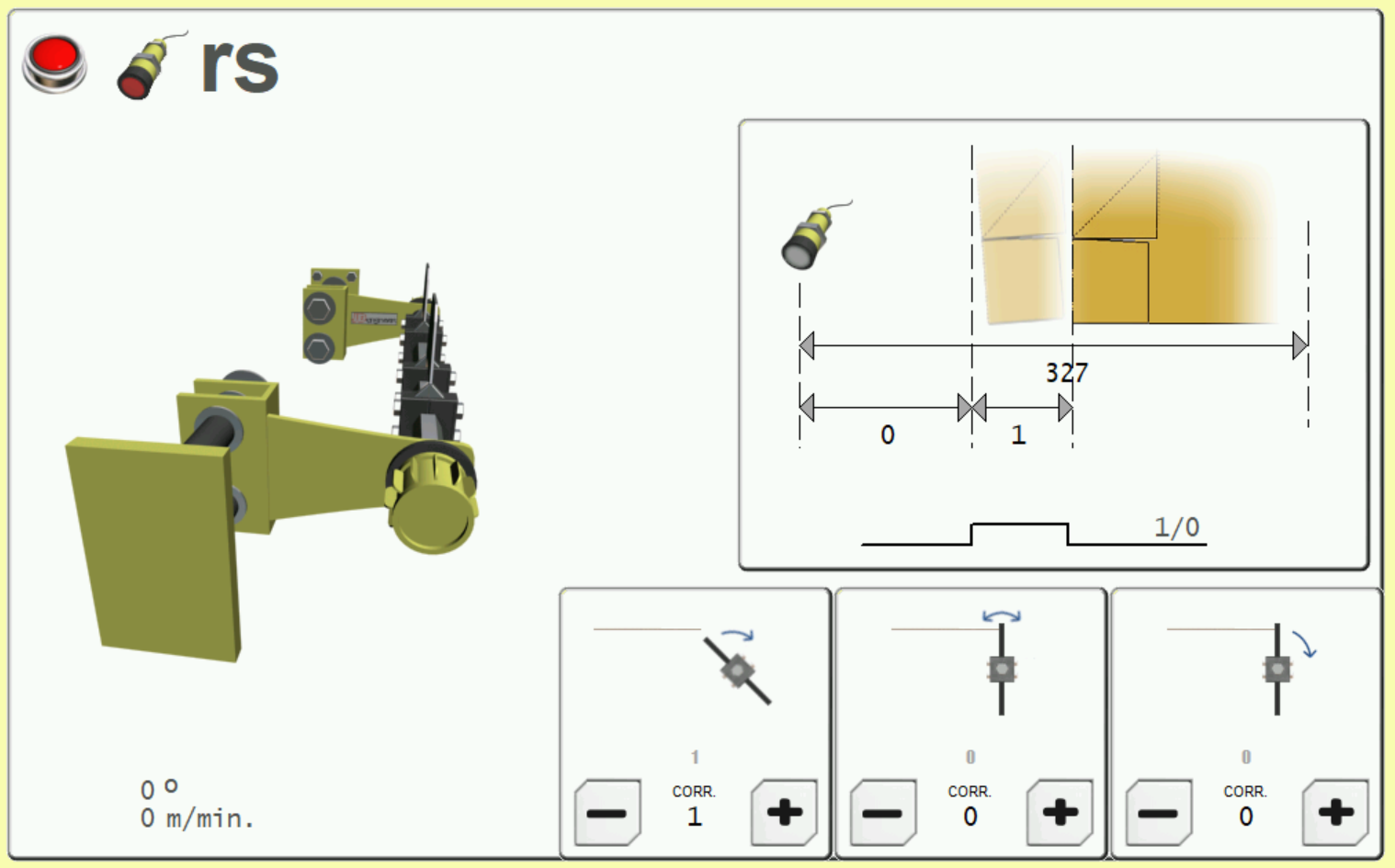

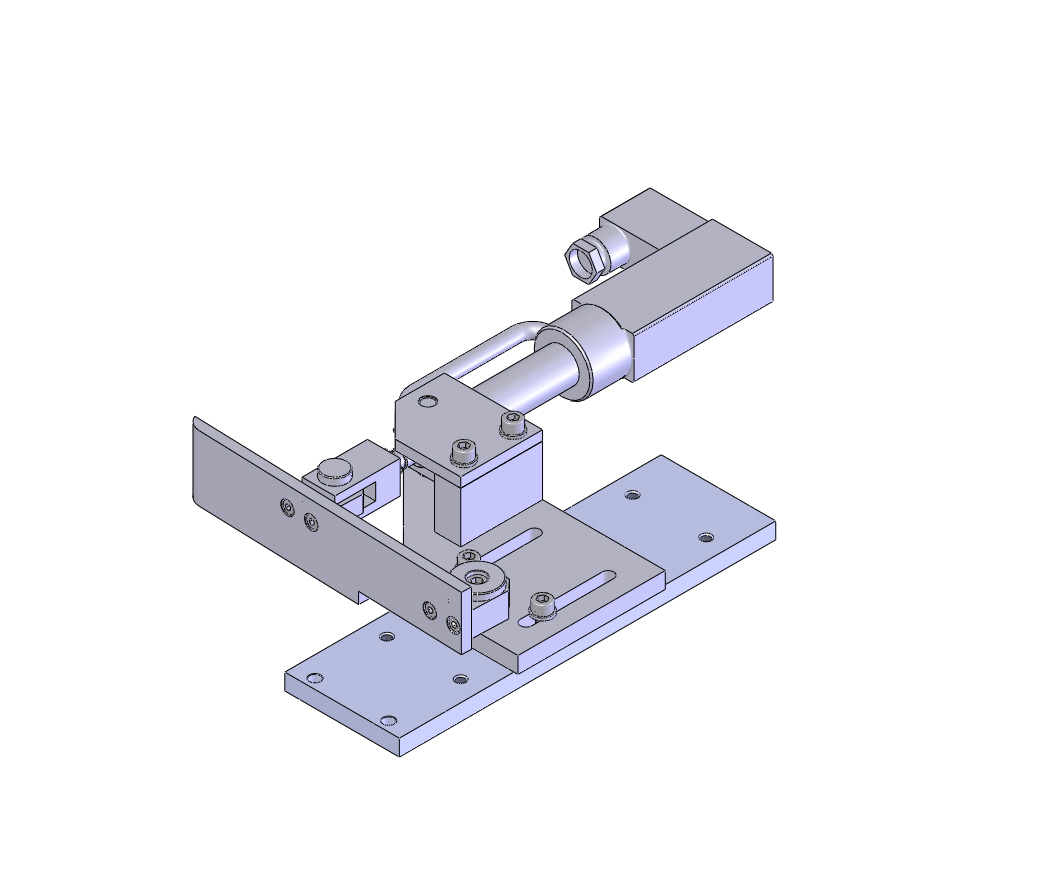

The servo driven Rotary stopper is specially designed for cases where the pneumatic Stopper is too slow. This straightener is specially designed for smaller boxes that run at high speed and is able to handle the boxes with minimal space between them. The system is able to process various types of boxes at high speed (up to 30,000 pcs/h). Depending on the type of box.

The kicker system is often mounted in the trombone section to kick a folded box slightly to the left or to the right.

The JD stopper system contains 3 stopper modules in case of 3 transports. In the case of 2 transports, the system consists of 4 modules. If no output is available on the machine, an additional control element is necessary.

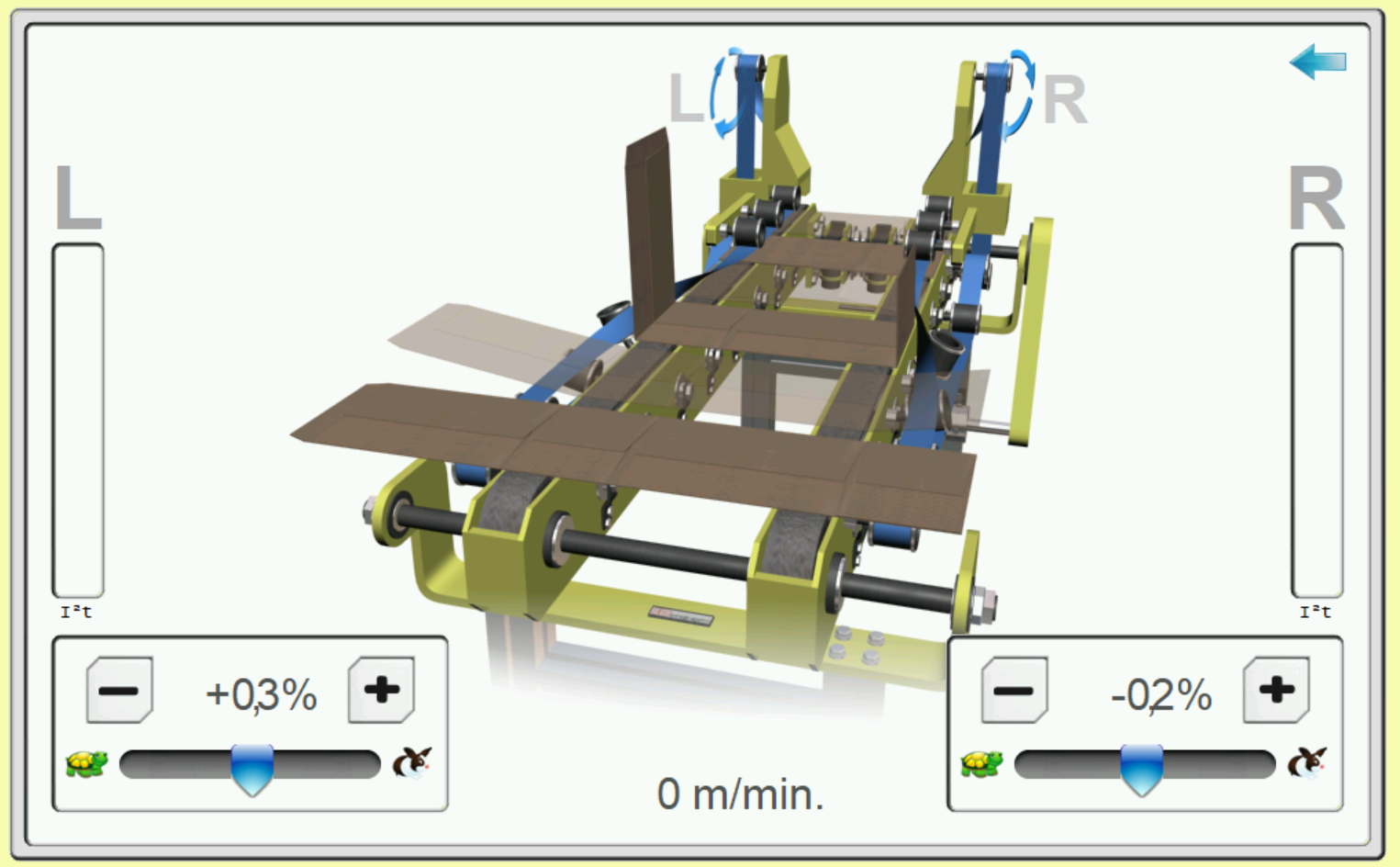

The folding belt control is a flexible solution to regulate the speed of the folding belts. Both belts can be adjusted independently of each other, even during production (on the flow). Settings are entered on the touch screen and will be stored into the memory.

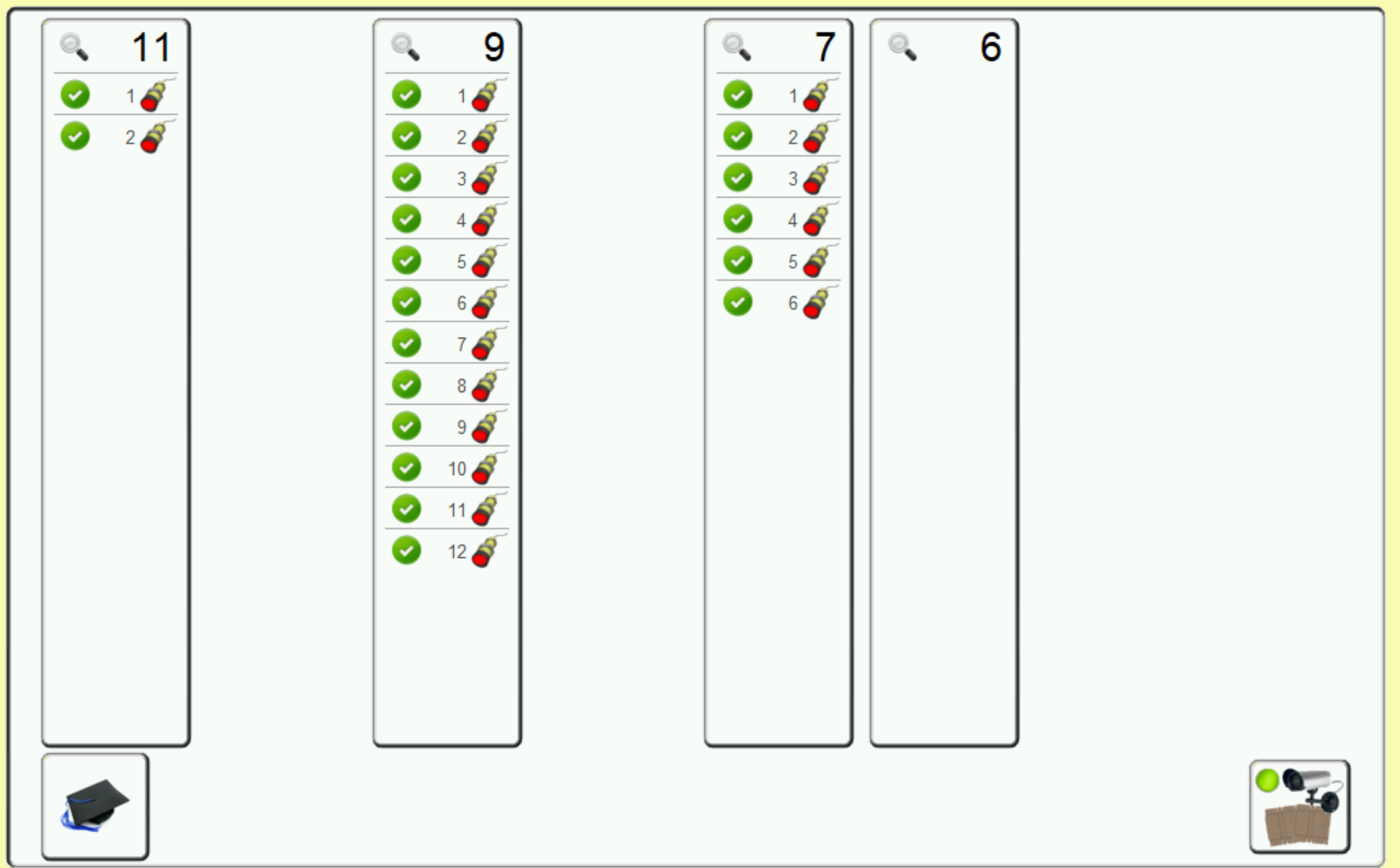

The Glue detection uses optical sensors to measure the length and position of glue on the blank during production. In case an unacceptable difference is detected the machine will be (partly) switched off. Signal lights can be connected and a message, with time stamp, will be logged. Standard a total of 16 optical sensors can be connected to the system

The auto set is a absolute measure sytem for all the frames with an excellent accuracy.

In case the existing frame computers are still in a good shape, some types can be integrated into the JD main control.

In other situations the frame computers will be replaced by new touch screens to operate the frame setting but other settings can be done from this screens as well.The Jam detection uses optical sensors to measure the length of the blank during production. In case an unacceptable difference is detected that could lead to damage, the machine will be (partly) switched off. Signal lights can be connected and a message, with time stamp, will be logged. Standard a total of 16 optical sensors and 16 signal lights can be connected to the system.

When a machine is equipped with an ejection unit an incorrect folded box will be ejected from the product flow.

The T-Fold is a folding hook above the paper line. This hook will allow you to fold boxes over the full width of the blank. For example leak proof boxeswith a PE coating can be folded at high speed using the T-unit .

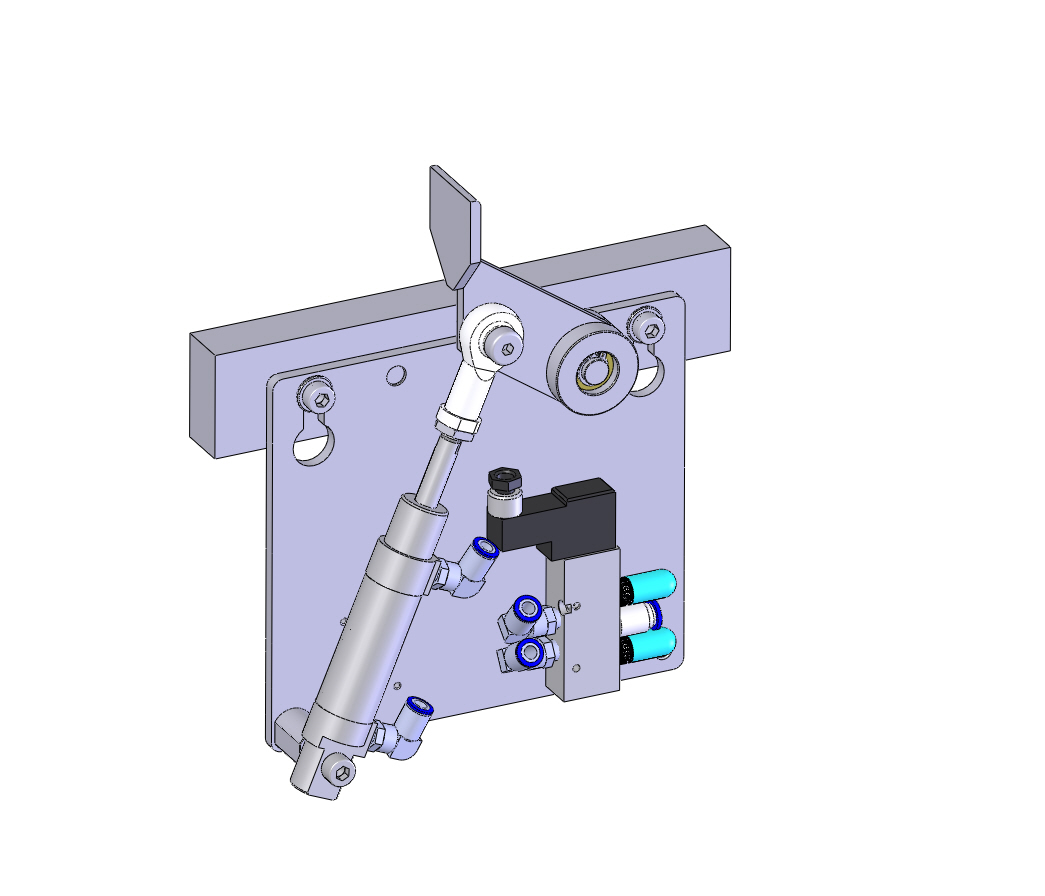

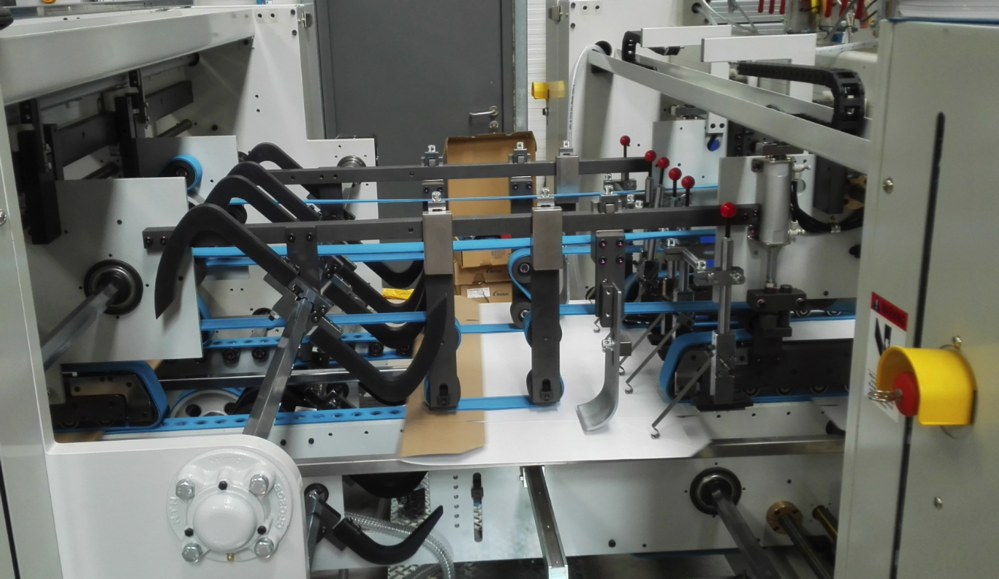

The Special fold is servo driven rotating front folding hook on a hexagon shaft. The special design ensures the front end will be folded perfectly. Mounting the hooks requires no tools because of the JD quick lock system.With this upgrade you will have the possibility to run boxes with minimal gap between the boxes.

The special fold allows high speed without the risk of “bouncing”front fold hooks and significant less noice. The settings are calculated by the JD Box editor and adjustments can be done “on the flow”.

A flexible solution to control the speed of the feeder belts. This control is an independent speed control for adjustable feeder belt speed.

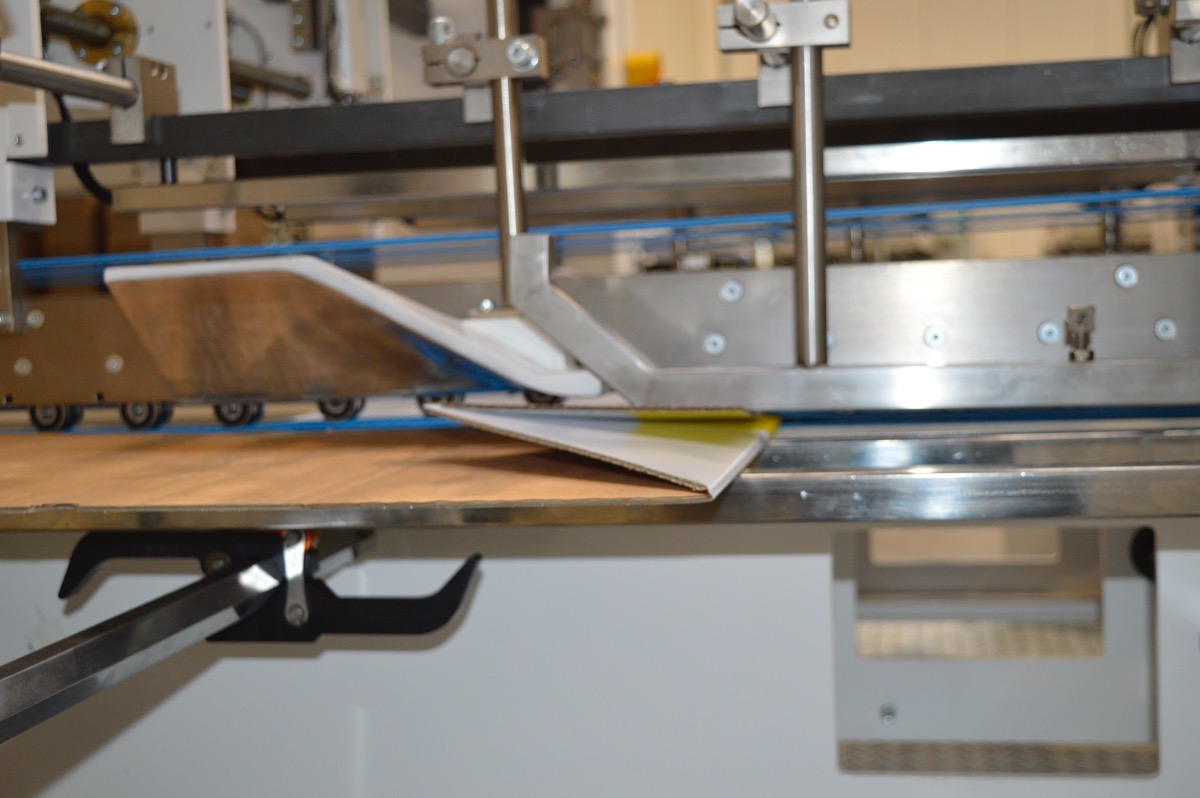

The servo driven Back-folding makes it possible to reduce the minimal distance between the blanks. This results in a higher output at the same belt speed. The backfold hooks can be mounted easily because of the JD quick lock system.

The settings are automatically calculated by the JD box editor. Adjustments can be done “on the flow”.

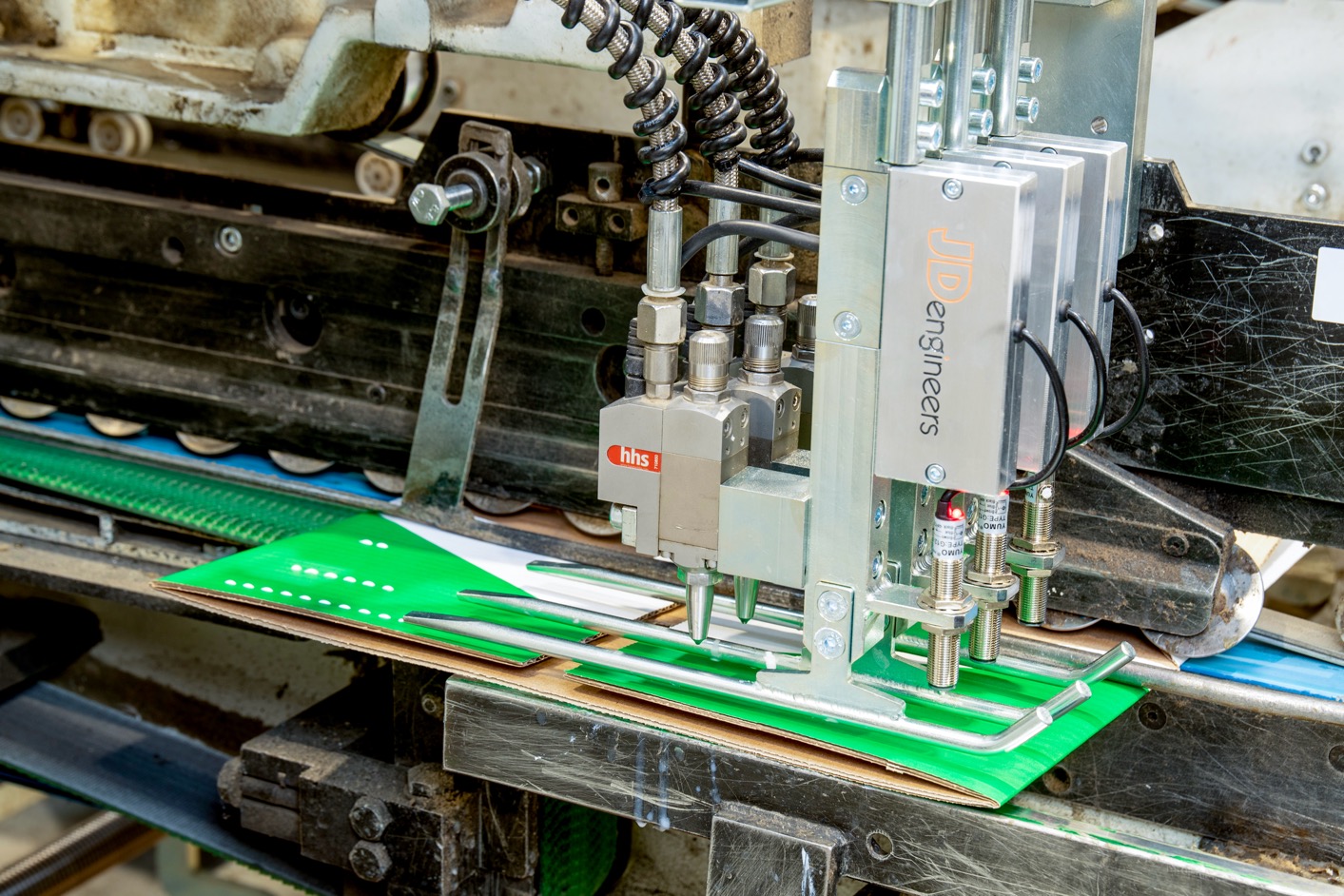

The glue control is developed for specialty folder gluers by JD engineers. It can control up to 16 glue guns. With the possibility to extend this to 32, 64 glue heads. With the Glue control almost every brand of glue gun can be controlled.. Wiring and tubing is integrated in to the machine. Connection to the system requires only 1 cable and a glue hose. A mix of hotmelt and PVA glue can be handled without a problem. Even if they are from different brands. The JD engineers glue inspection can be easily integrated ( a perfect match in combination with an ejection unit).